Elevator Pit Installation and Service by Hamilton Concrete Works

Hamilton Concrete Works is a leader in elevator pit installation and service, ensuring the safety, functionality, and reliability of this vital aspect of modern construction. Elevator pits are foundational to an elevator's operation, housing essential mechanical components and providing a safe environment for their function.

Materials and Specifics in Elevator Pit Design and Construction

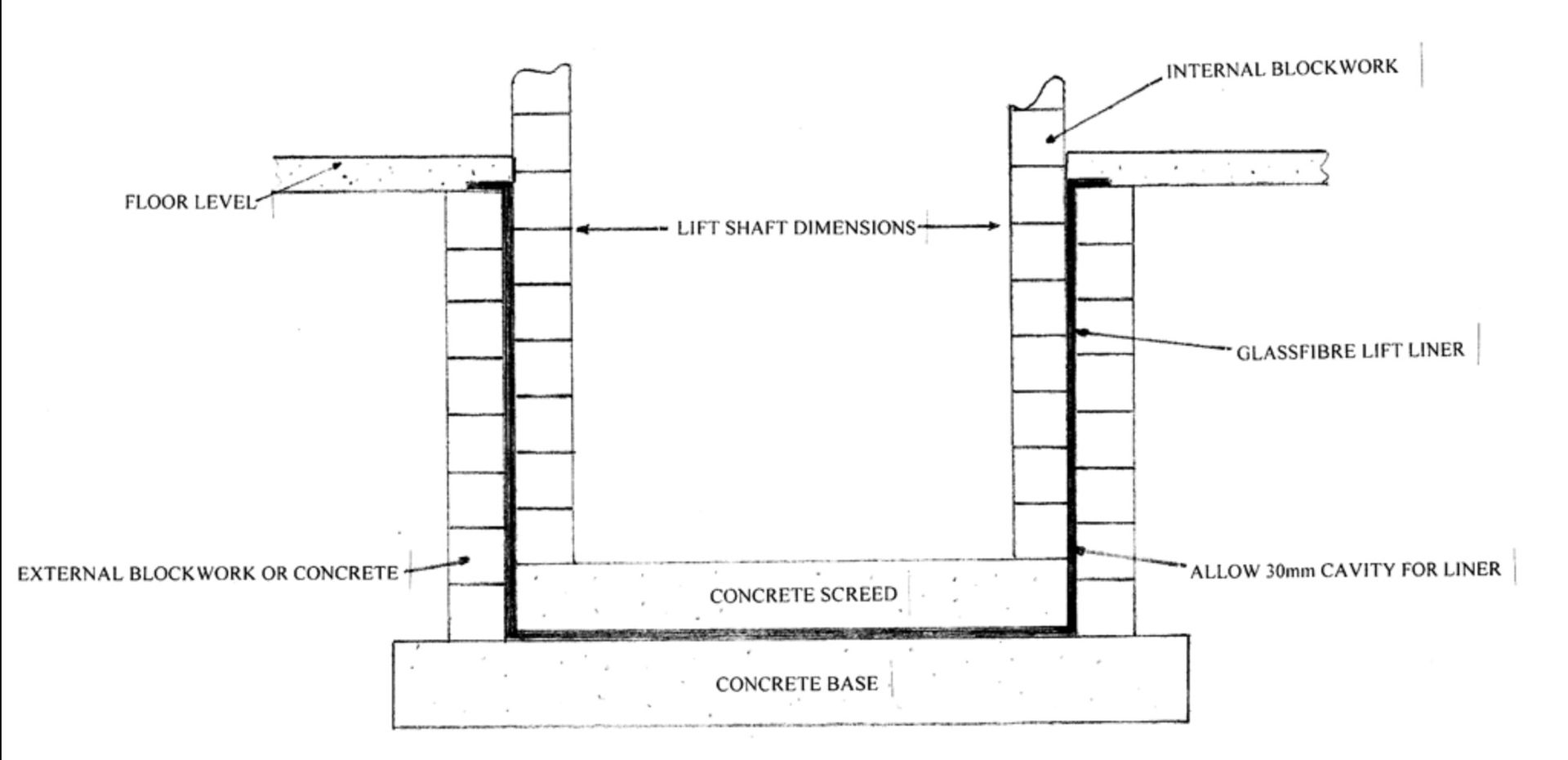

Our elevator pits are designed with precision, utilizing high-strength concrete usually rated at 4,000 psi or higher. The walls are often reinforced with steel rebars, providing an additional layer of strength and stability. The thickness of the concrete floor typically ranges between 6 to 8 inches, depending on the specific needs and size of the elevator. Waterproofing measures are taken, employing specialized membranes or coatings to prevent moisture penetration, a critical factor in maintaining the integrity of the elevator pit. The drainage system is designed to deal with potential water intrusion, usually consisting of a sump pit and pump.

Key Installation Considerations

Every elevator pit must comply with specific building codes and regulations, including adherence to precise measurements and tolerances. The dimensions are tailored to the elevator type, with standard pits usually being 4 feet deep. The alignment must be perfect to the millimeter, to ensure proper function and safety. The integration of a proper waterproofing system is vital to prevent any moisture damage to the elevator mechanisms.

Maintenance and Detailed Inspection

Regular maintenance and inspection of the elevator pit are mandatory to ensure continuous and safe operation. This includes cleaning the pit to remove any debris and examining the waterproofing system to ensure no leakage or water accumulation. Drainage systems must be routinely checked for clogs and proper operation. Structural inspections are also conducted to assess the concrete's integrity and the condition of the steel reinforcements, usually annually or in accordance with local regulations.

What Are the Benefits of an Elevator Pit?

- Safety: Elevator pits house essential mechanical components, including buffers and other safety mechanisms, that help stop the elevator car in the event of a malfunction.

- Functionality: The pit allows necessary clearance and space for the proper functioning of the elevator, enabling it to reach the lowest floor.

- Maintenance Access: Elevator pits provide vital access for maintenance and inspection of the elevator's lower machinery, ensuring ongoing safety and performance.

- Water and Debris Management: Properly designed pits include drainage and waterproofing to prevent water damage and accumulation of debris, both of which could interfere with the elevator's operation.

Why Are Elevator Pits Important?

Elevator pits are an integral part of an elevator system, facilitating the safe and smooth operation of the elevator:

- Mechanical Housing: They house crucial mechanical components that play a role in the stopping and operation of the elevator.

- Compliance with Regulations: Elevator pits must be constructed according to specific codes and standards, ensuring that the elevator operates within safe and regulated parameters.

- Prevention of Water Damage: The waterproofing and drainage features in the pit protect sensitive mechanical components from water and moisture, preventing malfunctions and potential safety hazards.

- Facilitation of Maintenance: The design of the pit allows for necessary maintenance access to the lower machinery and components, facilitating regular checks and service to keep the elevator running efficiently and safely.

Ready to Work with a Professional at Hamilton Concrete Works? Contact Now!

For an installation that meets the highest standards of quality, safety, and efficiency, trust Hamilton Concrete Works with your elevator pit project. Our expert team is ready to consult with you and provide a customized solution that fits your specific needs. Contact us today!