Window Well Installation and Service by Hamilton Concrete Works

Window wells serve essential functions, from enhancing safety to improving aesthetics. Hamilton Concrete Works is proud to offer specialized window well installation and service, meeting precise standards for residential, commercial, and industrial applications.

What are Window Wells? Understanding the Basics

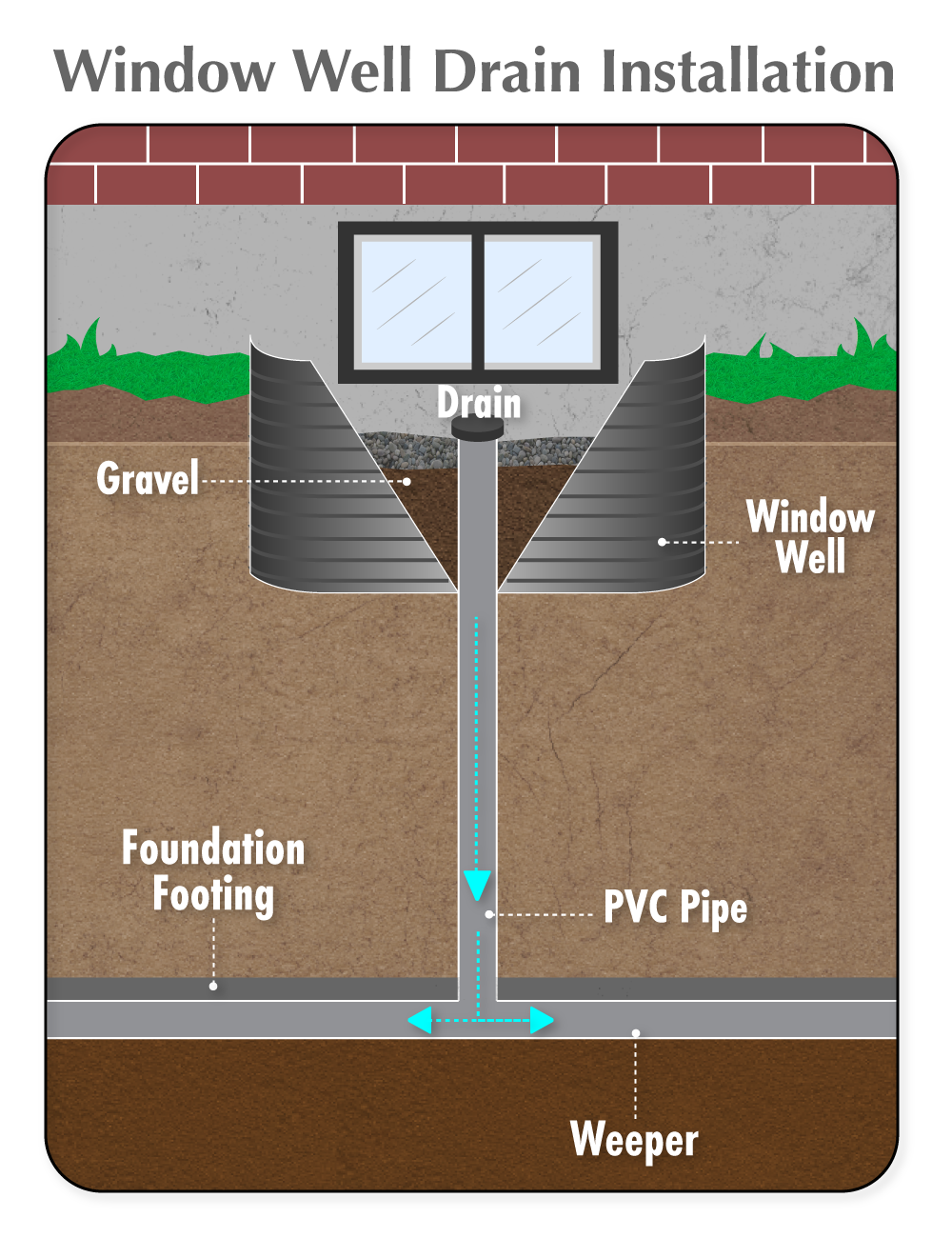

Window wells are specially designed structures that surround a basement window, providing a barrier against soil and water, and allowing light and air into the basement.

The Benefits and Importance of Window Well Drain Systems

Preventing Water Damage: Window wells keep rainwater and moisture from seeping into the basement.

Enhancing Safety: They provide an emergency escape route.

Improving Aesthetics: Available in various designs to beautify the property.

Materials and Specifics in Window Well Design

Galvanized steel window wells are often used, with a typical thickness ranging from 18 to 22 gauge. The advantages include high durability and rust resistance, with a lifespan of up to 20-30 years with proper maintenance. These are often coated with a layer of zinc for added protection against corrosion. Plastic or polyethylene window wells, generally around 1/8 inch thick, are also popular, being lightweight, rustproof, and able to resist UV rays. With adequate care, they can last 15-20 years. Concrete window wells, reinforced with steel bars, are known for their extreme durability and resistance to shifting.

Concrete Window Wells

Composition: Reinforced with steel bars to increase strength.

Advantages: Extremely durable and resistant to shifting over time.

Lifespan: Can exceed 30 years if regularly inspected and maintained.

Key Installation Considerations

Window wells should be precisely aligned with basement windows for optimal functionality. The ideal window well should extend 4-6 inches beyond the window's width and descend at least 8-10 inches below the window's sill. Drainage is a key consideration, often requiring a 2-4 inch layer of gravel at the bottom for proper water flow, along with a connected drainage system to prevent water pooling.

Maintenance and Detailed Inspection

The maintenance of window wells requires periodic cleaning to remove debris and maintain drainage efficiency, especially after seasons with heavy foliage drop. A biannual structural check for signs of wear, cracks, or rust is crucial, particularly in regions with harsh weather conditions. Additionally, an annual drainage assessment ensures that the drainage gravel remains unclogged, and the connected drain is functional.

Why Hamilton Concrete Works Stands Out

Hamilton Concrete Works offers a blend of experienced craftsmanship, premium materials, and technical know-how related to window wells.

When it comes to the safety, functionality, and aesthetic appeal of your window wells, don't compromise. Let the experts at Hamilton Concrete Works guide you with unparalleled expertise. Reach out today for a detailed consultation.