Concrete Driveway

We are your trusted partner for concrete driveway services in the Hamilton area. With years of experience and a commitment to excellence, we specialize in providing comprehensive solutions for all your driveway needs. Whether you require a new driveway installation, repairs, resurfacing, or decorative options, our skilled team is here to deliver outstanding results that enhance the beauty and functionality of your property.

Find out More About Your New Concrete Driveway in Hamilton

Driveway Repair Solutions You Can Trust

Does your driveway show signs of wear, like cracks, potholes, or surface imperfections? Trust in our experienced team to diagnose and deliver efficient repair solutions. We do crack sealing, patching, to comprehensive resurfacing.

Driveway Maintenance & Sealing

To maximize your driveway's lifespan, we offer robust maintenance and driveway sealing solutions. From surface cleaning to minor repairs, our team ensures your driveway is in prime condition. We apply a premium sealant, tailored to your driveway’s specific needs, protecting it against weather, UV damage, and daily wear. Whether it's acrylic, epoxy, penetrating, or polyurethane sealers, we recommend what's best.

Commitment to Excellence & Customer Satisfaction

Your satisfaction is our topmost priority. Reach out to Hamilton Concrete Works for a free consultation and quote. Experience the distinct advantage of partnering with a leading concrete contractor committed to unmatched quality and service.

Why to Install a Concrete Driveway

Opting for a concrete driveway is both a practical and aesthetic choice for any property owner. Here's why:

- Concrete driveways are a long-lasting investment, celebrated for their robustness that can endure for decades. The material's versatility means that it's not limited to the standard gray. Instead, it can be tailored to various finishes, seamlessly integrating with the surrounding architecture.

- Concrete offers tangible advantages. Its light-colored surface improves nighttime visibility, and specific finishes provide enhanced traction, ensuring safety for both pedestrians and vehicles. For those concerned about environmental impact, concrete driveways leave a smaller carbon footprint, blending sustainability with durability.

- Maintenance concerns are minimal with concrete. Apart from occasional upkeep and sealing, they withstand diverse weather conditions, from scorching sun to heavy rainfall. Their resistance to common driveway nuisances, like oil and petrol spills, ensures longevity with less wear and tear.

- In the broader perspective of property valuation, a well-laid concrete driveway suggests meticulous care and can enhance market value. It's not merely a path to your home but a reflection of the thought and investment you've poured into your property.

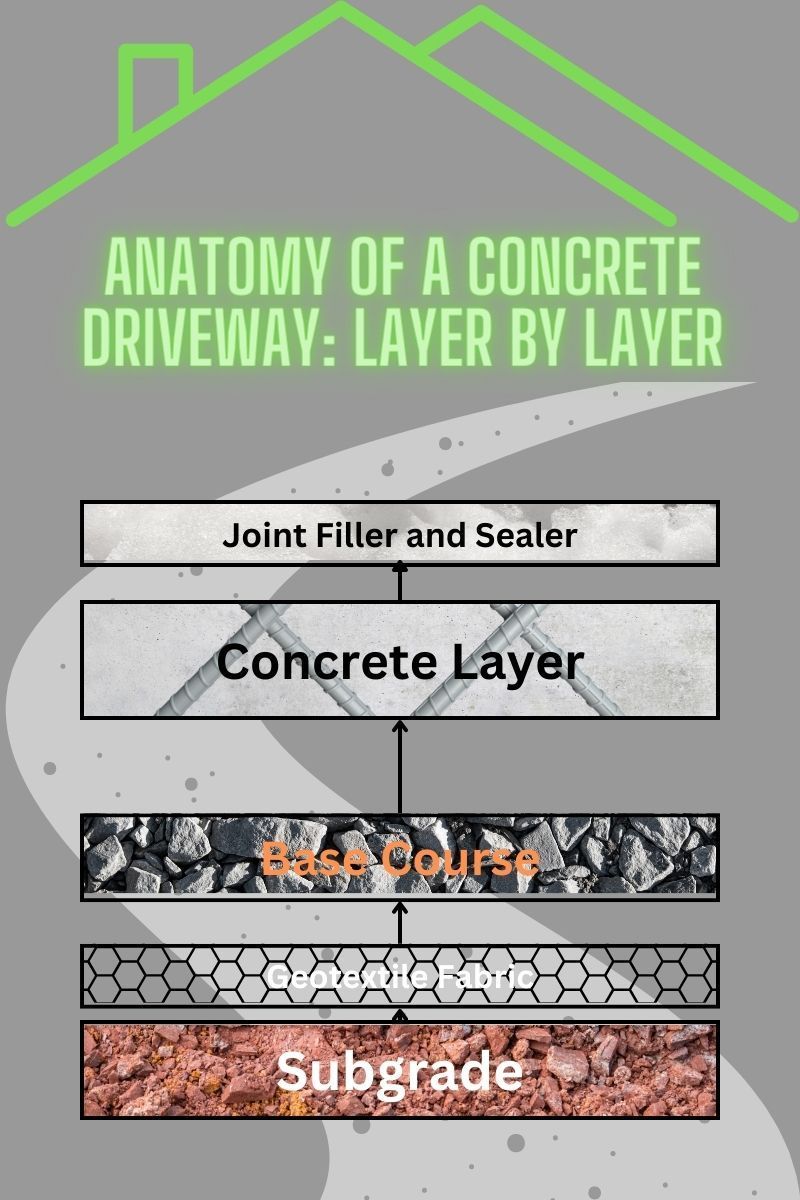

Our Concrete Driveway Installation Process

Concrete Driveway Finishes

Stamped Concrete

- cost-effective option for adding texture and flair to your driveway.

- Installation range from $90 to $140/m^2

- The textured finish adds design elements and provides improved traction for walking and driving.

- Regular rinsing or occasional low-pressure power washing may be required to keep the grooves free from dirt.

- Concrete color oxides can be added for a desired color finish.

Pavecut Concrete Service

- Pave cut finish offers homeowners the appearance of slate or pavers for their driveway.

- Can be combined with colored or brushed finishes for a modern style resembling natural slate.

- Size and pattern of the pave cut can be customized for a unique and personalized design.

- The pave cut lines are made using a diamond saw once the driveway has fully cured.

Exposed Aggregate Concrete

- Exposed aggregate offers a wide variety of texture options for driveways.

- An additive is mixed into the concrete to create a three-dimensional look with small stones, shells, or pebbles.

- The aggregate comes in various sizes and colors, allowing for a unique and customized appearance.

- Cost of an exposed aggregate concrete driveway ranges from $100 to $150/m^2,

- The final result is a textured, decorative, slip-resistant, and long-lasting driveway that can endure for many decades.

Plain Concrete

- Professionally poured and set concrete provides a clean and fresh look for driveways.

- Plain concrete is a popular choice due to its quick installation and cost-effectiveness.

- Cost for a plain concrete driveway typically ranges from $60 to $80/m^2

- Requires minimal maintenance and care to keep it in good condition.

- Proper sealing by a professional concrete service can extend its lifespan to at least 30 years.

Most dirt and grime can be easily washed away with a simple garden hose.

Want to Transform Your Space With a New Concrete Driveway in Hamilton, Ontario?

Our team of professionals is ready to speak with you and improve your space today! Don't hesitate and give us a call!