How to Choose the Right Type of Concrete for Your Project

How to Understand and Choose the Right MPA Rating for Your Concrete Project

Choosing the right type of concrete for a construction project is crucial for ensuring durability, cost-efficiency, and successful completion of the work. Whether you're laying a simple residential driveway or constructing the foundation for a commercial building, the type of concrete you use matters significantly. This guide will explore how to select the right MPA (megapascal) rating for your project to ensure safety, durability and success.

Understanding Concrete Strengths and MPA Ratings

What is MPA in Concrete?

MPA ratings help determine the compressive strength of concrete, which is essential for understanding how much load and stress the concrete can withstand. MPA stands for megapascal, a unit of pressure used to describe the compressive strength of concrete. Compressive strength is the capability of a material to withstand loads that tend to reduce size.

For concrete, this is a critical property as it defines its ability to bear loads without failure or significant deformation. Understanding the MPA rating of concrete is fundamental to ensuring that the material is fit for the purpose, tailored to withstand specific environmental conditions and structural demands.

Understanding the Different MPA Ratings and Their Applications

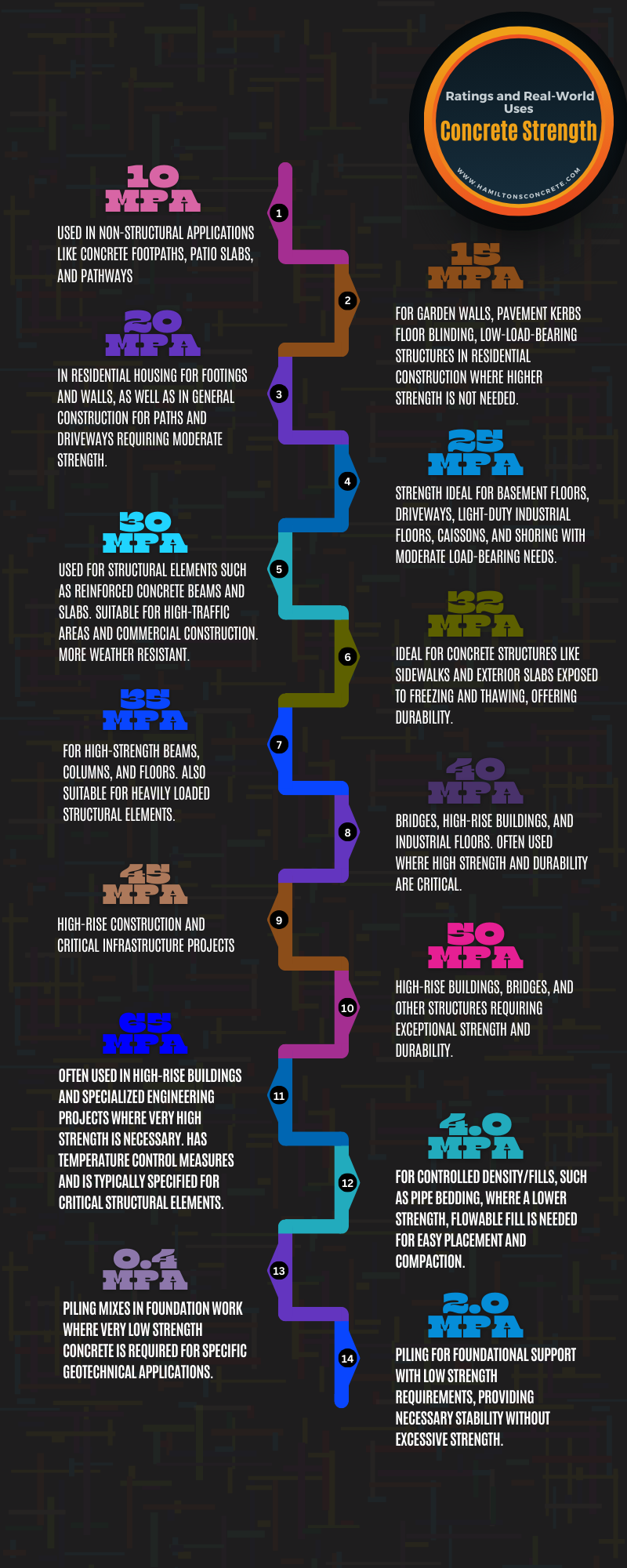

The MPA rating of concrete can significantly influence its application in a project. Here’s a brief overview of common MPA ratings and their typical uses:

- 10 MPa: This is generally used for non-structural and decorative applications where the concrete will not be subjected to heavy loads, such as garden pathways or residential landscaping features.

- 20 MPa: Commonly used in residential construction for structures like driveways, sidewalks, and garage slabs that need to withstand moderate loads.

- 25-30 MPa: This range is suitable for foundations and supporting structures of residential and light commercial buildings. It provides a good balance between strength and cost.

- 40 MPa and above: High-strength concrete used in heavy-duty commercial and industrial construction, such as bridges, high-rises, and infrastructures that must handle significant loads and stresses.

What Factors Influencing the Choice of MPA Rating

The choice of MPA rating is influenced by structural requirements, environmental conditions, and the expected lifespan of the project. For instance, foundations require higher MPA ratings than non-load bearing components, and harsh environmental conditions might necessitate specialized concrete mixes.

MPA Ratings for Different Projects

- Residential: 25-30 MPA is typically adequate for most home building applications including foundations and garages.

- Commercial and Industrial: Structures with heavy loads or critical operations often need 40 MPA or higher, especially in infrastructural projects like bridges and tunnels.

How to Calculate the Required MPA Rating

To determine the appropriate MPA rating; Consider both static and dynamic loads. Use engineering standards to accommodate unexpected load increases. Adjust the mix for specific environmental exposures. Ensure compliance with local regulations and get tailored advice.

Conclusion

Choosing the right MPA rating is vital for the structural integrity and longevity of any construction project. By understanding load requirements, environmental factors, and advancements in concrete technology, stakeholders can ensure their projects are both safe and sustainable.

Consult with a professional concrete contractor or service to select the ideal concrete mix for your project’s specific needs, ensuring durability and compliance.

What is the minimum MPA rating for a basement floor?

Basement FloorsFor basement floors, which require a moderate strength to handle general residential or light commercial use, a minimum of 25 MPA is typically recommended. This rating ensures durability against regular foot traffic and supports the weight of standard furnishings and equipment.

Can the MPA rating be customized for specific projects?

Yes, MPA ratings can be customized based on the specific needs of a project. This customization involves adjusting the concrete mix design to include different proportions of water, cement, aggregates, and admixtures, tailored to achieve the desired strength and performance characteristics. It's crucial to work with a skilled concrete supplier or a structural engineer to develop a mix that meets the precise requirements of your project.

How does MPA rating impact cost?

Generally, higher MPA ratings require more cement or specific high-grade materials, which can increase the cost of the concrete. However, investing in a higher MPA rating can be cost-effective in the long run by reducing maintenance costs and extending the lifespan of the structure. It’s important to balance the initial material costs with the long-term benefits of using a more durable concrete.

How does weather affect concrete choice?

Weather conditions play a significant role in selecting the appropriate concrete MPA rating. For example, in areas prone to freezing and thawing cycles, higher MPA ratings, combined with air entrainment and other freeze-resistant additives, are necessary to prevent cracking and structural damage. Similarly, in very hot climates, special admixtures may be required to slow the curing process and ensure proper strength development.

What should I look for in a concrete supplier?

When selecting a concrete supplier, look for one that offers a wide range of concrete mixes and demonstrates comprehensive quality control measures. Good suppliers will provide detailed specifications for their mixes, including MPA ratings, and will support custom mix designs. Additionally, check for positive customer reviews and a strong reputation in the industry to ensure reliability and quality service.

Are there environmentally friendly concrete options?

Yes, there are several environmentally friendly concrete options available that still meet required MPA ratings. These options often use recycled materials, such as fly ash or slag, as partial replacements for cement, or incorporate aggregates made from recycled concrete. Some suppliers also offer low-carbon cements that significantly reduce the greenhouse gas emissions associated with concrete production.

Are Ready To Work With HAMILTON CONCRETE WORKS?

Let's get in touch!

Send us a message and we’ll be in touch.

Or give us a call today at 289-204-1632