Ready-mix Concrete: The Ultimate Guide

Introduction

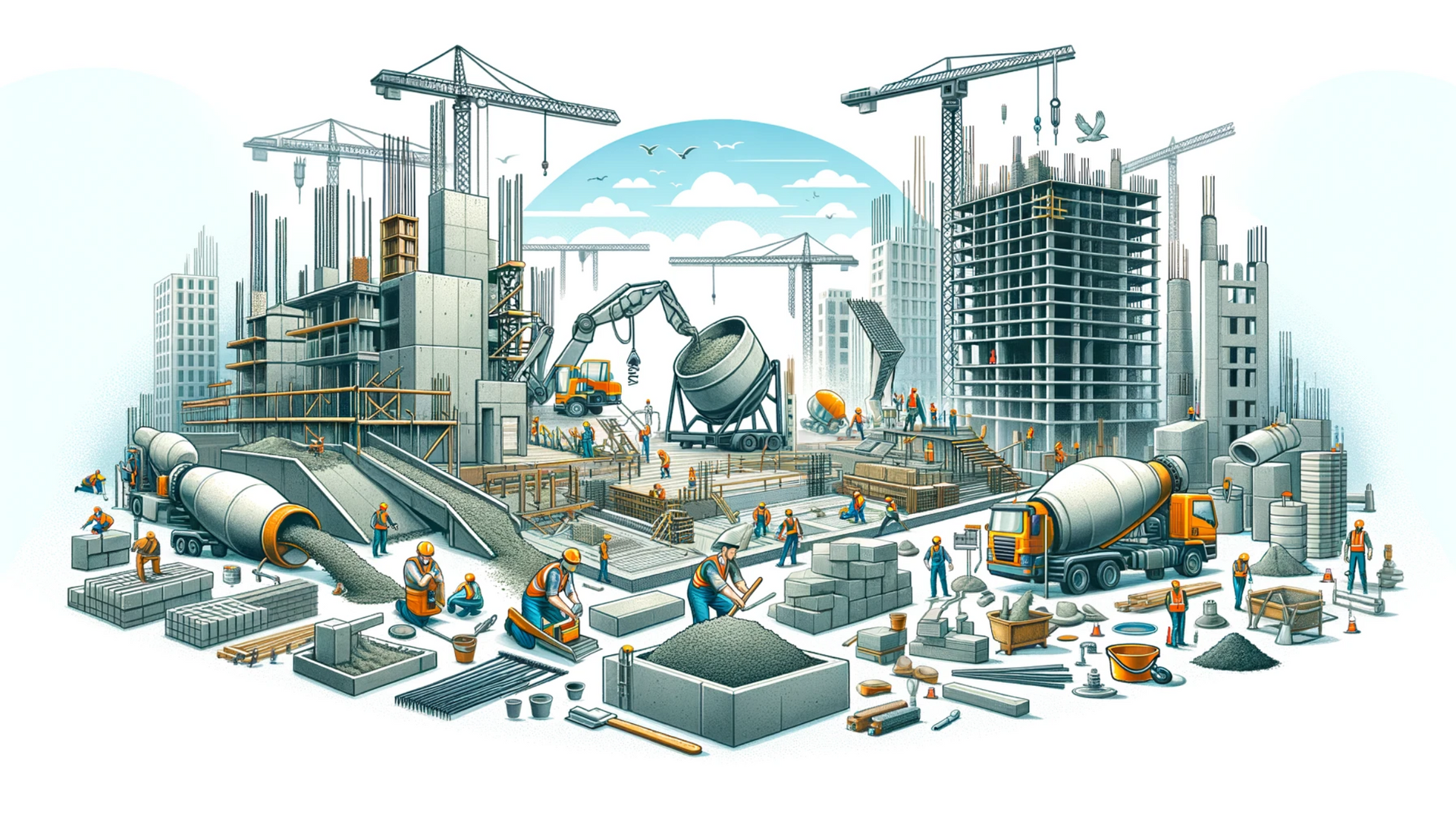

Ready-mix concrete is a game-changer in the construction industry. This versatile material offers convenience, consistency, and time-saving advantages for builders and contractors. In this article, we will dive deep into the world of Ready-mix concrete, exploring its composition, applications, benefits, and environmental impact. Whether you're a seasoned construction professional or a DIY enthusiast, this guide will equip you with the knowledge to make informed decisions when using Ready-mix concrete in your projects.

What is Ready-mix Concrete?

Ready-mix concrete, also known as RMC, is a tailor-made concrete mixture produced in batching plants or concrete factories according to precise specifications. The ingredients, including cement, aggregates, water, and chemical admixtures, are mixed in predetermined proportions to ensure consistent quality and performance. Once mixed, the concrete is transported to the construction site in specialized trucks, where it can be directly used for various applications.

The Components of Ready-mix Concrete

To understand Ready-mix concrete better, let's break down its components:

1. Cement

Cement serves as the binding agent in Ready-mix concrete. It is a fine powder that, when combined with water, forms a paste that binds the aggregates together. Ordinary Portland cement is the most commonly used type in RMC production.

2. Aggregates

Aggregates, comprising crushed stone, gravel, sand, and recycled materials, give RMC its structural strength. Different sizes and types of aggregates are carefully selected to achieve the desired concrete properties.

3. Water

Water activates the cement and allows it to bind with the aggregates, creating a solid matrix. The right water-cement ratio is crucial to ensure the concrete's strength and workability.

4. Chemical Admixtures

Chemical admixtures are added to Ready-mix concrete to modify its properties. They can enhance workability, improve durability, reduce curing time, and provide resistance to harsh weather conditions.

The Benefits of Ready-mix Concrete

Utilizing Ready-mix concrete in construction offers numerous advantages:

1. Time Efficiency

RMC eliminates the need for on-site concrete mixing, saving valuable construction time. With Ready-mix concrete, you can start construction immediately upon delivery.

2. Consistent Quality

The computer-controlled batching process in RMC production ensures consistent proportions and superior quality. This consistency minimizes variations and enhances the structural integrity of the final product.

3. Reduced Labor Costs

As RMC is pre-mixed, the requirement for on-site labor for concrete mixing is significantly reduced. This reduction in labor translates to cost savings for construction projects.

4. Environmentally Friendly

Ready-mix concrete plants employ eco-friendly practices, including recycling waste materials and using energy-efficient processes. Additionally, the precise mixture proportions reduce material wastage.

5. Enhanced Strength and Durability

The controlled manufacturing process of Ready-mix concrete results in a concrete mix with optimized strength and durability, ensuring the longevity of the structure.

6. Versatility

RMC is highly versatile and can be customized for various applications, such as foundations, driveways, roads, bridges, and more.

Applications of Ready-mix Concrete

Ready-mix concrete finds extensive use in diverse construction projects due to its adaptability and consistency. Some key applications include:

1. Residential Construction

In residential construction, Ready-mix concrete is used for building foundations, floors, walls, and other structural components.

2. Commercial Construction

For commercial buildings, RMC is employed in the construction of offices, shopping complexes, hotels, and warehouses.

3. Infrastructure Development

In infrastructure projects, such as roads, bridges, highways, and airports, RMC is preferred for its strength and durability.

4. Industrial Projects

In industrial settings, RMC is used for constructing factories, manufacturing plants, and storage facilities.

5. Decorative and Architectural Elements

Ready-mix concrete can be colored, stamped, or textured to create decorative elements like driveways, patios, and pathways.

Tips for Using Ready-mix Concrete

When working with Ready-mix concrete, consider the following tips to ensure optimal results:

1. Adequate Site Preparation

Before pouring RMC, ensure that the construction site is well-prepared, with proper formwork and adequate compaction.

2. Proper Curing

Curing is crucial for the concrete to develop its full strength. Keep the concrete moist and protect it from extreme weather conditions during the curing period.

3. Timely Placement

RMC is a time-sensitive material. Coordinate with the concrete supplier and construction team to ensure the timely placement of the concrete.

4. Workability Enhancers

For complex construction projects, consider using workability enhancers like plasticizers or superplasticizers to improve concrete flow and ease of placement.

5. Expert Consultation

When dealing with specialized projects or challenging conditions, consult with experienced engineers or concrete experts to ensure the right concrete mix design.

Conclusion

Ready-mix concrete is undoubtedly one of the most revolutionary advancements in the construction industry. Its versatility, consistent quality, and time-saving benefits make it an attractive choice for a wide range of projects. From small DIY ventures to large-scale infrastructure developments, RMC continues to play a significant role in shaping the modern world.

So, the next time you embark on a construction project, consider the numerous advantages of Ready-mix concrete, and you'll be well on your way to building a solid foundation for success. Check out the rest of our website to learn more: Concrete Services

FAQs (Frequently Asked Questions)

Are Ready To Work With HAMILTON CONCRETE WORKS?

Let's get in touch!

Send us a message and we’ll be in touch.

Or give us a call today at 289-204-1632