Self-Leveling Concrete: The Ultimate Guide

Self-leveling concrete is a modern solution that has revolutionized the way we approach flooring and surface preparation. It's a must-have for anyone looking to achieve a perfectly flat surface without the time-consuming and labor-intensive traditional methods. In this guide, we'll explore everything you need to know about self-leveling concrete, from its composition to its applications.

What is Self-Leveling Concrete?

Self-leveling concrete is a polymer-modified cement that has high flow characteristics and, in contrast to traditional concrete, does not require the addition of excessive amounts of water for placement. It's used to create a smooth and flat surface with a compressive strength similar to or higher than that of traditional concrete.

Composition

Here's a breakdown of the typical composition of self-leveling concrete:

- Cementitious Material: 40-50%

- Aggregates: 30-40%

- Polymers: 5-10%

- Additives and Admixtures: 5-10%

- Water: 20-25%

Applications

Self-leveling concrete is widely used in various residential and commercial applications. Some of the common uses include:

Benefits of Self-Leveling Concrete

1. Time-Saving

Traditional concrete leveling can be a time-consuming process. Self-leveling concrete, on the other hand, is quick to apply and settles into a flat and smooth surface without the need for extensive manual labor.

2. Versatility

It can be used over various substrates, including concrete, wood, and tiles, making it a versatile solution for different surfaces.

3. Durability

With proper installation and maintenance, self-leveling concrete can last as long as traditional concrete, providing a durable and resilient surface.

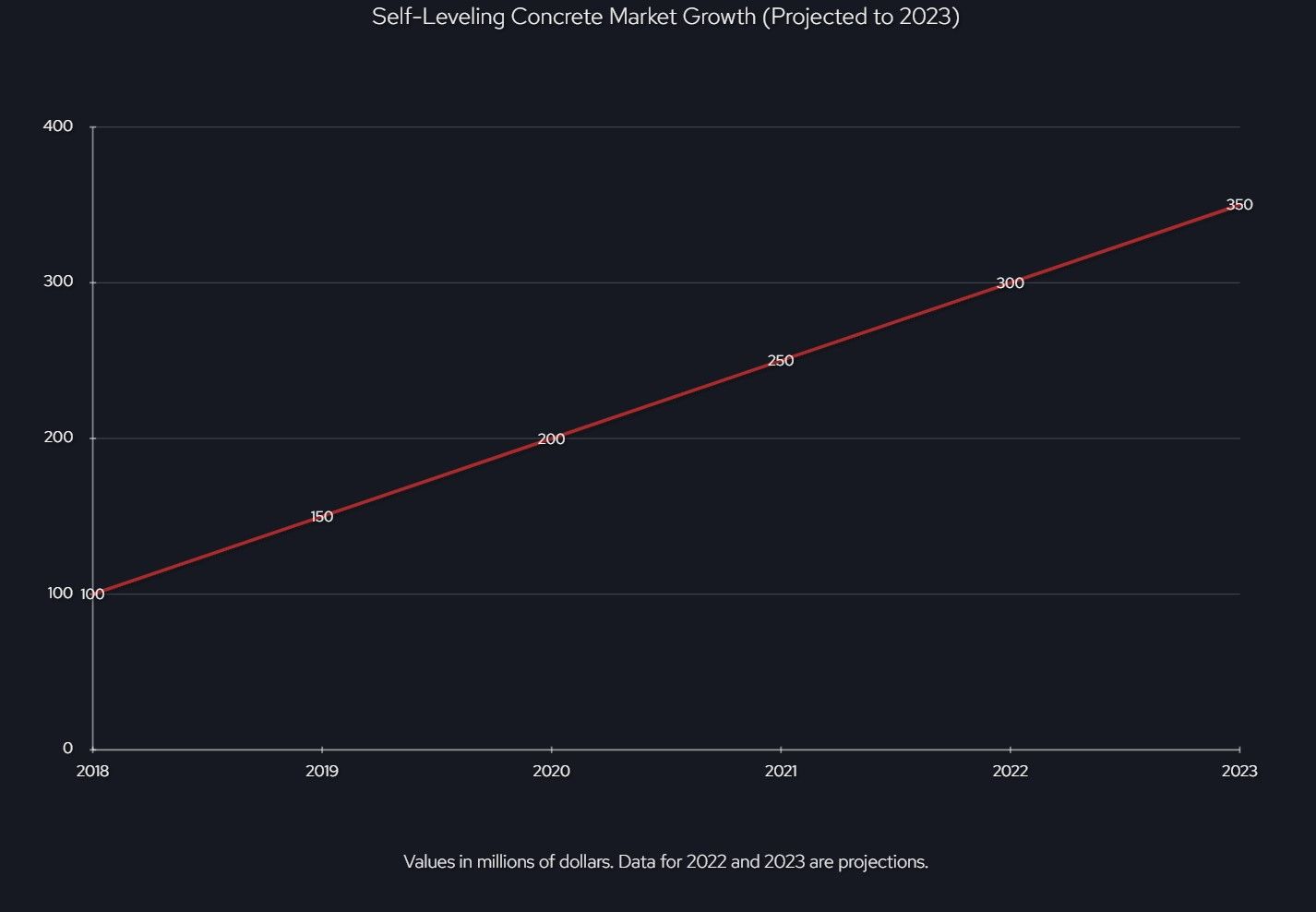

Visualizing the Market Growth

The popularity of self-leveling concrete has been on the rise, especially in the commercial sector. Let's take a look at the market growth over the past few years.

The chart above illustrates the steady growth in the market for self-leveling concrete. It's clear that more and more builders and homeowners are recognizing the benefits of this innovative material.

Self-leveling concrete is not just a trend; it's a practical solution that offers efficiency, versatility, and durability. Whether you're a homeowner looking to renovate your concrete patio and porch or a commercial builder in need of concrete resurfacing, self-leveling concrete could be the perfect solution for you.

Installation Process and Best Practices

The success of a self-leveling concrete project lies in the proper installation. Understanding the process and following best practices can make the difference between a smooth, level surface and a flawed, uneven one. Let's dive into the step-by-step guide to installing self-leveling concrete.

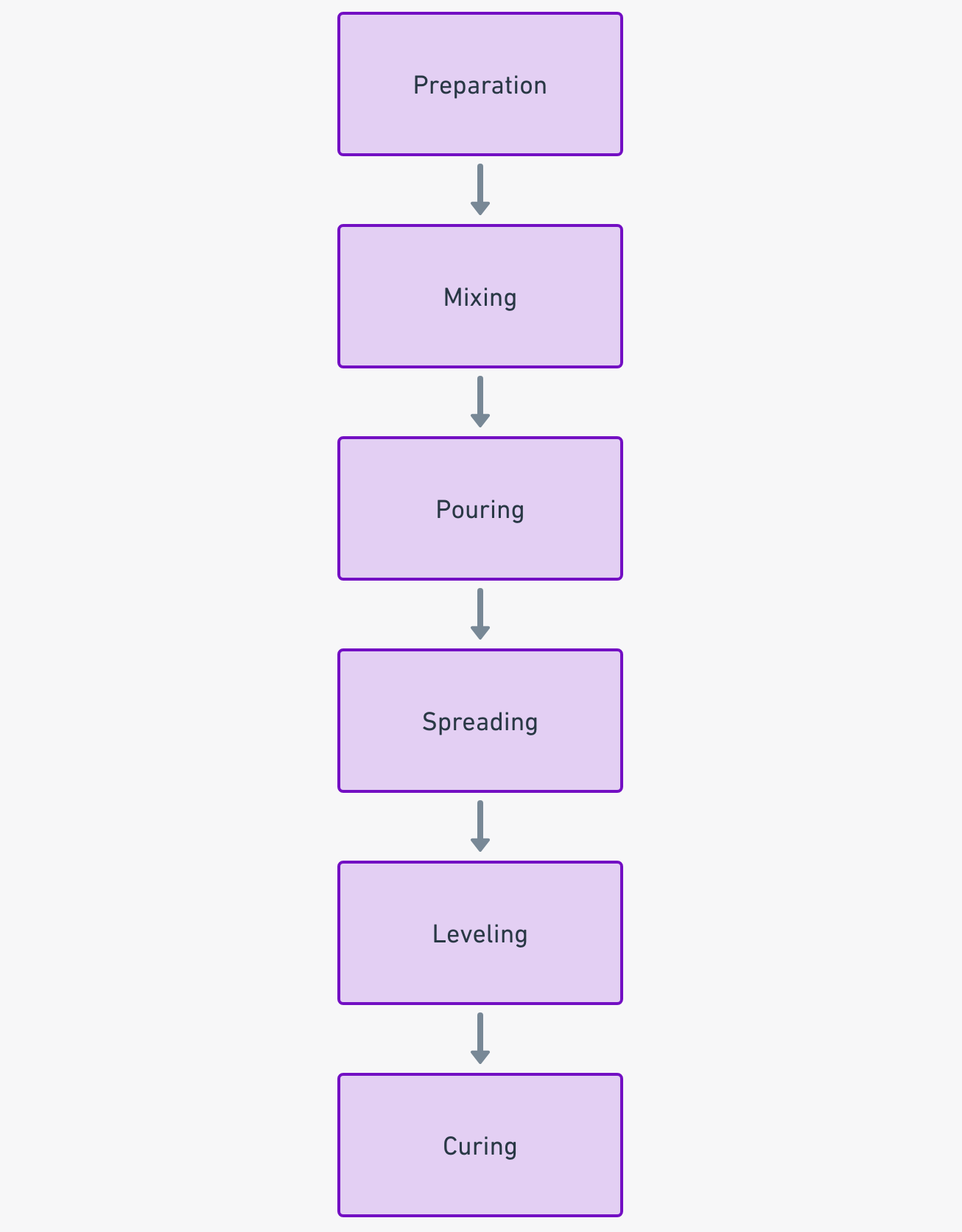

Step-by-Step Guide to Installation

Step 1: Surface Preparation

Before applying self-leveling concrete, the surface must be clean, dry, and free of any contaminants such as oil, grease, or dust.

- Clean: Use a broom or vacuum to remove loose debris.

- Inspect: Check for cracks and repair them with a suitable patching compound.

- Prime: Apply a primer to ensure proper bonding with the self-leveling concrete.

Step 2: Mixing

- Measure: Follow the manufacturer's instructions for the correct ratio of water to mix.

- Mix: Use a drill with a mixing paddle to blend the self-leveling concrete until it's lump-free.

- Rest: Allow the mix to sit for a few minutes to release any air bubbles.

Step 3: Pouring

- Pour: Start from one corner and pour the self-leveling concrete onto the surface.

- Spread: Use a gauge rake or trowel to help spread the material.

- Smooth: A smoother can be used to break any surface tension and help the material level itself.

Step 4: Curing

- Protect: Keep the area free from foot traffic for at least 2-4 hours.

- Cure: Allow the surface to cure for the time specified by the manufacturer, usually 24-48 hours.

Common Mistakes to Avoid

- Ignoring Manufacturer's Instructions: Always follow the guidelines provided by the manufacturer for the best results.

- Skipping Surface Preparation: Proper preparation is key to a successful installation.

- Adding Too Much Water: Over-watering can weaken the mix and lead to problems down the line.

Best Practices

- Use Quality Products: Invest in high-quality self-leveling concrete and related products.

- Hire Professionals: If unsure, consider hiring professional services like Hamilton Concrete Works for concrete floor and slabs installation.

- Monitor Temperature: Follow the manufacturer's guidelines for temperature and humidity during installation.

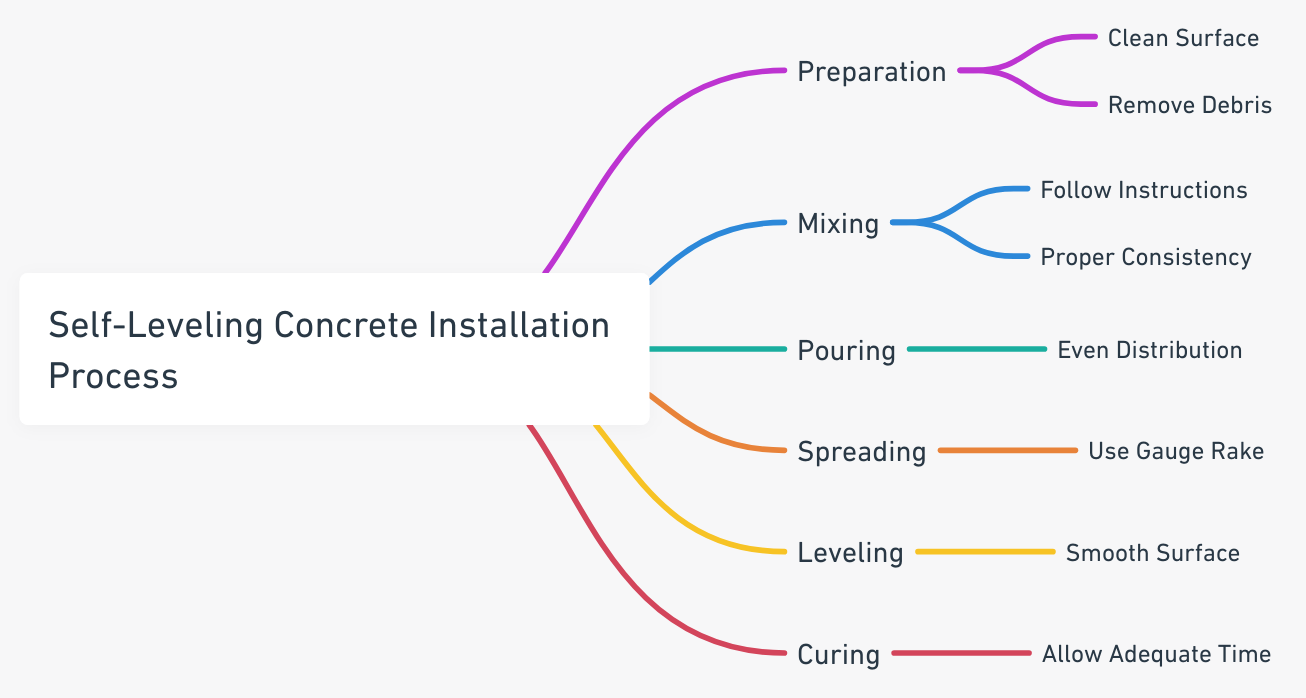

Visualizing the Installation Process

Here's a to visualize the importance of each step in the installation process:

Installing self-leveling concrete is a precise task that requires attention to detail and adherence to best practices. Whether you're looking to enhance your concrete driveway or need concrete resurfacing, following the guide above can help you achieve a flawless finish.

Maintenance and Care of Self-Leveling Concrete

Once you've successfully installed self-leveling concrete, the journey doesn't end there. Proper maintenance and care are essential to preserving the appearance and functionality of the surface. Whether it's a concrete patio and porch or concrete garage floors, here's what you need to know to keep them in top shape.

Regular Cleaning

Regular cleaning is the cornerstone of maintaining any concrete surface. Here's a simple routine:

- Sweep: Use a soft-bristle broom to remove loose dirt and debris.

- Mop: Use a damp mop with a mild detergent to clean the surface.

- Rinse: Rinse thoroughly with clean water to remove any soap residue.

- Dry: Allow the surface to air dry or use a dry mop to remove excess water.

Preventive Measures

Taking preventive measures can go a long way in preserving the integrity of the surface.

- Use Mats: Place mats at entrances to minimize dirt and grit.

- Avoid Harsh Chemicals: Use pH-neutral cleaners to avoid damaging the surface.

- Protect from Heavy Loads: Use protective pads under heavy furniture or appliances.

Periodic Maintenance

In addition to daily care, periodic maintenance can help prolong the life of the surface.

- Inspect for Damage: Regularly check for cracks, chips, or other signs of wear.

- Seal if Necessary: Depending on the type of finish, a sealer might be required to protect the surface.

- Consult Professionals: Schedule regular inspections with professionals like Hamilton Concrete Works for concrete resurfacing or other maintenance needs.

Dealing with Common Problems

Even with diligent care, problems can arise. Here's how to deal with some common issues:

| Problem | Solution |

|---|---|

| Stains | Use a mild detergent and soft brush to gently scrub the stain. |

| Cracks | Small cracks can be filled with a suitable patching compound. Consult a professional if needed. |

| Surface Discoloration | This may require professional assessment and treatment, such as concrete renovation services. |

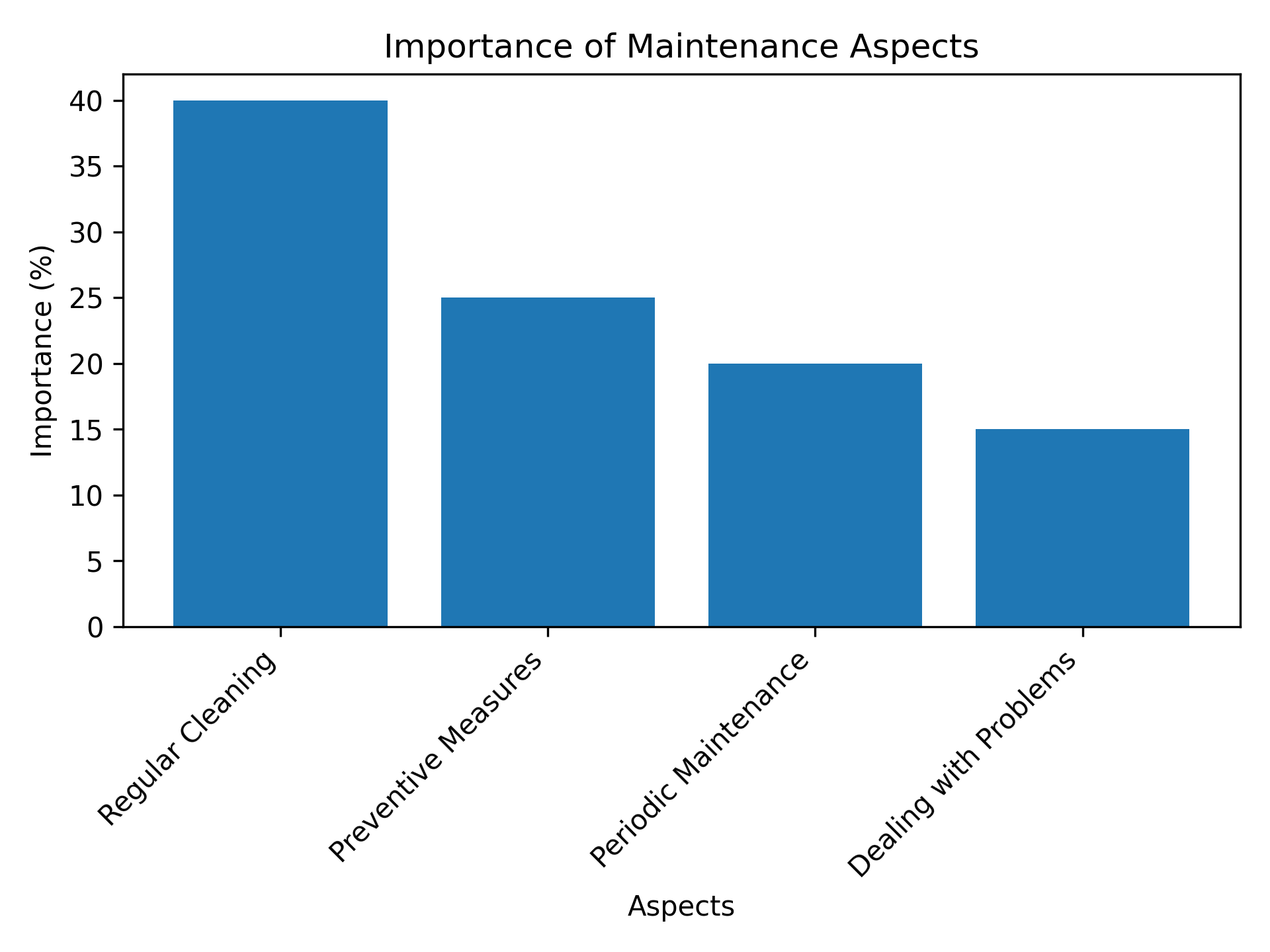

Visualizing Maintenance Importance

Let's visualize the importance of different maintenance aspects through a bar graph:

Conclusion

Maintaining self-leveling concrete is not a daunting task, but it does require regular attention and care. By following the guidelines above, you can ensure that your concrete floor and slabs or concrete sidewalk and walkway remain beautiful and functional for years to come.

Whether you're a homeowner or a commercial property manager, understanding the maintenance needs of self-leveling concrete is essential to maximizing your investment.

Are Ready To Work With HAMILTON CONCRETE WORKS?

Let's get in touch!

Send us a message and we’ll be in touch.

Or give us a call today at 289-204-1632